Product Description

1.Our company provides 30-40TPD fully automatic rice mill production line. From paddy cleaning to rice packing, the operation is automatically controlled. Good quality, reasonable price, and professional technical support should be provided. It can produce rice 30-40 tons per day.

2.The Complete Rice Mill Production Line is a kind of comprehensive equipment for rice processing. Rice goes into machine through vibrating screen and magnet unit, and then forward under rubber-roller for hulling. Winnowing and air blowing to husk. The machine may complete all the processing works from cleaning grain, rice husking in hulling to rice husking in succession. As to husk, chaff, blighted grain as well ad polished rice, they are all pushed out of machine separately. This machine is comprehensive expression for all the good qualities of varied kinds of rice-processing machines. For instance, it is arranged with a comprehensive view of situation and is designed rationally.

3.Our rice milling machines have been sold all over the world.As long as there is rice,there are our machines.From the plant drawing design,machines installations and after-sales services,we all have enjoyed good communications and established long terms cooperation with our customers already.

4. With advanced technology, the high quality of unit machine,high white rice yield,excellcnt polished rice quality and low price,our complete set of rice milling equipment series 18TPD to 200TPD,or rice mill with other higher capacity can be provided with customers' demands.

5. Anon 100 TPD can make 100 tons of rice per day , it should work on 380V, 50hz, 3 phases. We can make customized voltage for different countries.

| Pre Cleaning | Removing all impurities and unfilled grains from raw paddy |

| De-stoning | Separating small stones from paddy |

| Husking | Removing husk from paddy |

| Husk Aspiration | Separating the husk from brown rice/ unhusked paddy |

| Paddy Separation | Paddy Separation |

| Whitening | Removing all or part of the bran layer and germ from brown rice |

| Polishing | Improving the appearance of milled rice by removing the remaining bran particles and by polishing the exterior of milled kernel |

| Color Sorting (Optional) | Removing foreign materials such as colored, broken, immature and insected grains from milled rice |

| Length Grading | Separating small and large brokens from head rice |

| Blending | Mixing head rice with predetermined amount of brokens, as required by the customer |

| Weighing and Bagging | Preparing the milled rice for transport to the customer |

Main Parameters

| Main Machines for Anon 30-40TPD Rice Mill Production Line | |||

| Machine Name | Quantity(Set) | Power (KW) | Capacity (TPH) |

| Combined Cleaner | 1 | 2.2 | 2.2 |

| Paddy Husker | 1 | 4 | 1.8-2.5 |

| Gravity Paddy Separtor | 1 | 1.5 | 1.5 |

| Rice Whitener | 1 | 22 | 1.7 |

| Rice Whitener | 1 | 18.5 | 1.2-3 |

| Rice Grader | 1 | 1.1 | 1.2-1.7 |

| Rice Color Sorter (Optional) | 1 | 2 | 1-4 |

| Rice Water Polisher (Optional) | 1 | 30 | 30 |

| Rice Packing Scale (Optional) | 1 | 5-50KG/Bag | 300-500 Bags/Hour |

More Options

| Parboiling (Optional) | Improving the nutritional quality and milling recovery percent during husking and polishing / whitening operation |

| Paddy Dryer | Drying raw paddy with high moisture |

| Thickness Grader | Removing broken and immature grains from brown rice before whitening |

| Flow Scale | Flow controlling and incontinuous accumulating measure of white rice |

| Hammer Mill | Milling chaff into grainy materials |

| Rice Hull Separator | Separating paddy and broken brown rice from husk |

| Bran Separator | Separating broken rice from rice bran |

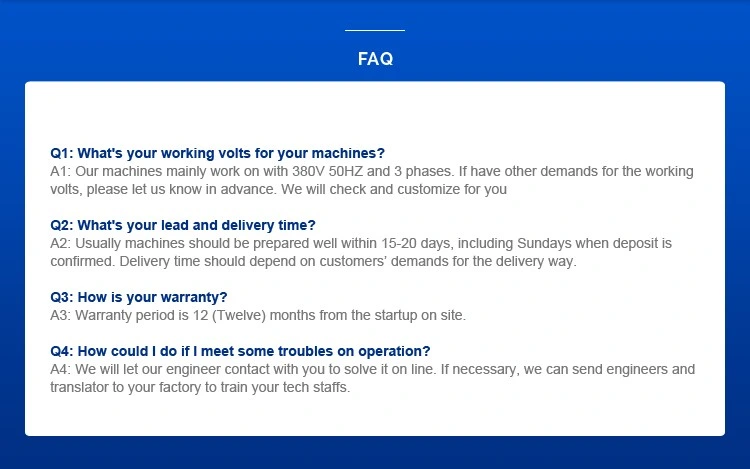

Processing Flowchart

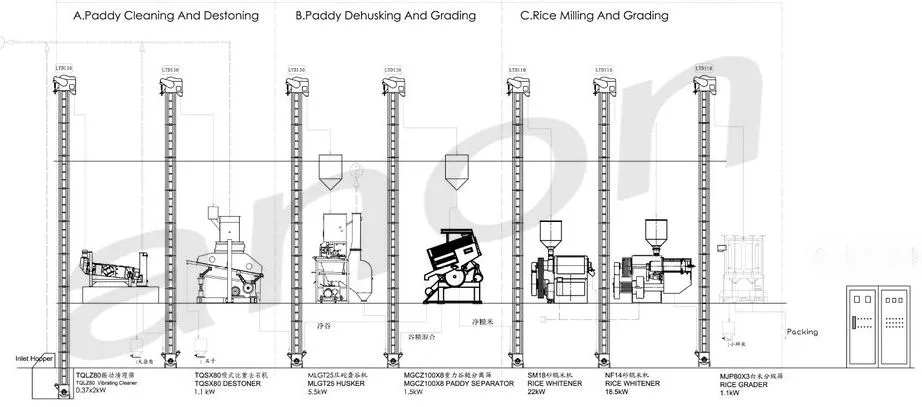

Equipment Details

Rice Mill Plant Pictures

Why choose Anon

1.Rich manufacturing experience with competitive price.

Over 15 years manufacturing experience with CE&ISO9001 certificates.

Win-Win strategy provides competitive price with high quality guaranty.

2.High performance and long working life equipments.

The new rice milling technology and good quality material,result in

super steady performance,less rate of broken rice,long working life,beautiful rice.

3.Full technical support.

Anon provides technical support including:

land planning--factory design--equipments installation--equipments operation training--maintenance.

4.Best after-sale service.

Anon provide 24 hours after-sale service in 365 days,any problems will be dealed with within one day occured.

Certificates Display

Customers Visits

FAQ